English

Proprietary Annealing Processes to meet the Most stringent requirements.

Provides oxidation free parts through high temperature hydrogen processes.

Fully computerized control of the annealing process.

Specialized processes designed to suit your specific requirements.

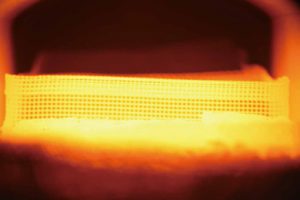

Heat treating furnace

Heat treatment with hydrogen Gas

The heating in the conveyor belt furnace

We have the capacity to handle both small and large contracts.

Since we operate 24hour a day we provide extremely rapid turnaround for our clients.

Retort furnaces

Vertical heat treatment unit

Facility instead of factory

Conveyor belt furnaces

Our process prevents the deformation of processed parts.

Brass screw stress relieving

Armature alignment for devices

Shield alignment for manual

Bright solution heat treatment

Corporate Profile

| Company Name | Thermal Chemical Industry Co,.Ltd |

|---|---|

| Representative | Takanori Ishii |

| Main Business,Activities and Products | Hydrogen atmosphere heat treating. Capabilities include magnetic annealing, bright annealing, solution heat treatment, quenching, stress relief and baking. |

| Head Office | 1-18-3 Hayase, Toda-Shi, Saitama 335-0036,Japan |

| Contact Person | Yasuhiko Saito |

| Phone | 81-48-421-4880 |

| FAX | 81-48-421-4881 |

Products and Technologies

The utilization of hydrogen gas eliminates oxidation.

We design our processes to your specific project.

Our 24 hour operation and computerized process ensures rapid turnaround while maintaining the highest quality.

process Permalloy parts

Permalloy lamination parts

Permalloy thin process

We have extensive experience working with specialized alloys such as Permalloy.

We are experienced in working with stainless steel, Inconel and non-ferrous metals.

Our process removes distortion and stabilized the microscopic inconsistency of your parts.

We can anneal a variety of materials and our process eliminates the need for further expensive and the time consuming further processing such as electro polishing and acid pickling.

We have an ongoing Research and Development program, in order to facilitate your specific requirements.

Consider us your partner in the in the production of high quality parts.

We have an extensive quality control program to ensure your parts meet the highest possible requirements.

Company Profile

Thermal Chemical Industry “Annealing”

Annealing are heat treating processes where a material’s mechanical properties are changed, lowering strength hardness.

Annealing is used to induce ductility, soften a material, relieve internal stresses,and refine the structure by making it homogeneous.

We will reduce or eliminate cold working properties.

It is performed by heating a metal or metal alloy above its re-crystallization temperature.

Soaking for a prescribed period of time, followed by cooling.

The cooling rate is determined by material that is being annealed.

Hydrogen gas atmosphere conducts annealing for various materials in a furnace for many different industries.

During the annealing, hydrogen gas atmosphere furnace is used to prevent oxides from forming on the surface of the material where would be detrimental in its intended use.

The process always starts from approximately room temperature, and heating rates are easily controlled to allow stress to be relieved slowly.

Gas cooling imparts much stress into a material than traditional liquid quenching, meaning less distortion occurs during the cooling portion of the annealing.

We advantages of annealing are minimize distortion.

Thermal Chemical Industry has been in business for over 40 years and is considered the expert in the hydrogen gas atmosphere heat treating industry because of the high regard for quality and customers.

Please contact us for assistance with all annealing.

Industries served

- Automotive (Hybrid, Electro, and other)

- Casting

- Drawn parts

- Electronics

- Medical

- Stamping

- Materials processed

- Metals

- Metal powders

- Ferrous and non ferrous metals